Steam production and hot water systems are crucial in industrial and commercial heating and cooling systems.

Industrial heating and cooling systems are critical in many manufacturing and production processes. These systems control the temperature and maintain a specific environment in which products are produced, stored, or processed. However, these systems emit a significant amount of heat released into the atmosphere as waste heat.

Steam production is used in various industries to provide heat and power, including food and beverage processing, chemical manufacturing, and pharmaceuticals. Steam is generated by boiling water, typically using boilers that burn fuel such as natural gas, propane, or oil. The steam is then distributed throughout the facility using pipes, which can be used for heating, cleaning, or driving turbines to generate electricity.

The use of hot water systems is similar, but instead of steam, hot water provides heat. These systems are standard in hospitals, hotels, and other facilities that require a constant hot water supply. Boilers generate the hot water and circulate it through pipes, radiators, heat exchangers, or other heating elements.

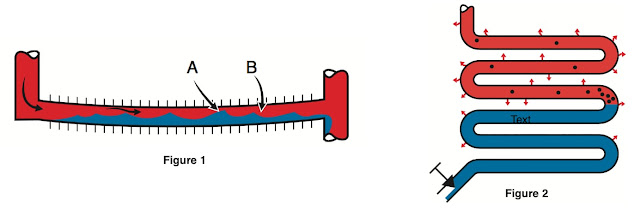

Industrial heating and cooling systems generate significant amounts of wasted or unused heat. There are measures to mitigate the causes of waste heat in industrial heating and cooling systems and reduce its release. One solution is to recover the wasted heat and use it for other purposes, such as heating or cooling nearby buildings or other industrial processes. Another solution is to improve the heating and cooling system's efficiency, reducing the energy required to maintain the desired temperature through more efficient heating and cooling systems, insulation, and enhanced equipment design. Also, by connecting your heating and cooling systems, you recover wasted heat and put it back into your industrial process.

Armstrong's Circular Thermal℠ significantly improves the thermal efficiency of your facilities. It reduces your need for primary energy by capturing and recirculating waste heat within your plant and toward your production. It significantly impacts your site's thermal decarbonization roadmap by reducing — and sometimes eliminating — the required purchase of renewable energy.

Learn more about Armstrong's Circular Thermal℠ here. To discuss more about Armstrong's approach to steam and hot water thermal efficiency in the Rocky Mountain states, contact Energy-West Controls. Call them at 800-533-4477 or visit https://energy-west.com.