Operators face problems and challenges with API emergency shutdown valves in remote locations where conventional energy sources are unavailable for automation. It is critical for the pipeline's safe operation that such valves can shut down the line when anomalies in the pressure of the gas passing through the pipe occur.

Valves usually are left open. If the line pressure drops or spikes, the system would use stored pressurized hydraulic fluid to close the valve as an emergency shutdown. These old antiquated systems presented several issues that made these highly critical valves inefficient. The main problem was that the system would not hold the valves open for more than two to three days due to internal leakage of the hydraulic system. These actuators would start to drift and prematurely close the valve, requiring the operators to physically go to these remote locations every two days to recharge the system and fully open the valve again. These valves mustn't suddenly close during regular operation and disrupt the flow throughout these midstream pipeline distribution networks.

Cowan Dynamics worked with an operator to review the requirements and recommend a superior design.

Here is a list of the challenges.

- This application presents a lack of conventional energy sources due to these valves' remote location.

- High torque and high thrust requirements make other power sources, such as solar power, unviable.

- The agricultural setting mandated a zero fugitive emissive solution.

- The operators required a drop-in retrofit, adding an extra layer of complexity to the challenge as these valves were underground and not readily accessible.

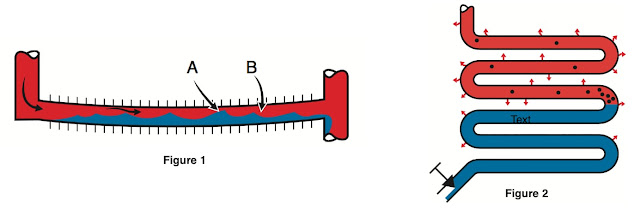

Cowan developed a solution named the ZE-ESD module. The solution consisted of a hydraulic accumulator, a 3000 psi rated actuator from Cowan's series MLA specially designed hydraulic manifold complete with a reservoir, a leakage compensating small accumulator, and a hand pump that serves as a power source to pressurize the accumulator and actuate the valve. The hydraulic circuit design significantly reduces pressure drops in the system due to thermal expansion or leakage throughout hydraulic components.

Cowan's ZE-ESD system proved a great success. The unique design of the hydraulic circuit far exceeded the original seven-day target. After 12 days of testing, the system only experienced a drop in the main pressure of three percent. After a month of installing the system, the customer advised that the valve needed recharging just once.

Another issue is environmental compliance. Environmental agencies establish stringent emission standards, often imposing heavy fines on those in violation. A large part of these fugitive emissions stems from gas-powered actuators' exhaust. As a result of these economic and environmental implications, Cowan Dynamics and Energy West Controls are committed to helping operators tighten their grip on fugitive emissions. Engineered to comply with API and ISO standards, Cowan's industry-leading range of zero-emission hydraulic modules for quarter-turn and linear valves are certified for maximum compliance with minimum environmental impact.

For more information, contact:

Energy West, Inc.

1955 West Industrial Circle

Salt Lake City, Utah 84104

Phone: 801-262-4477

Fax: 801-261-0862

Web: https://energy-west.com